A vineyard in the Central Coast of California had a partially open-air pump engine house. Although agricultural equipment is categorically exempt from local noise Codes, our Client wanted to be a good neighbor and sought out 45dB Acoustics to develop a mitigation strategy to reduce the noise propagating towards neighbors on the adjacent property. Due to budget constraints, the Client wanted to utilize the existing structure surrounding the pump engine and fuel tank to mitigate the noise.

The existing pump house has a raised roof with a continuous gap all around the top of the walls. The “walls” are corrugated sheet metal with metal mesh in some places. Any noise mitigation requires sealing up open-air flow to the extent possible in order to block noise. Fortunately, noise reduction was not needed in all directions from the pump house, since neighbors were located in only one direction. This allowed for a targeted mitigation treatment of the pump house while allowing some of the metal mesh walls and gaps at the roof to remain open for airflow to the large pump engine, which requires significant cooling.

45dB Acoustics worked with Pacific Sound Control to develop a cost-effective solution for the client. “Acoustic blankets” provide an additional benefit over simple batt-insulated plywood walls—acoustical absorption of sound reflections. With completely reflective surfaces of sheet metal and the concrete pad, noise blankets with the combination of noise blocking to reduce outdoor noise propagation beyond the property, as well as absorption for some reduction of noise levels within the pumphouse, was desirable. Also, another added benefit over a conventional structure is that these blankets allow reconfiguration and re-use in other noise control situations that may arise for the client across their vineyards, as noise sources and situations change in the future.

As mechanical equipment often has significant tonal noise qualities, mitigation of mechanical equipment should take into account the frequency or frequencies of interest. Error! Reference source not found. shows the 1/3-octave spectra acquired from a Type 2 (survey grade) meter—with the only potential tone or tone(s) being within the 200Hz band. In selecting a product that would target this frequency band, 45dB Acoustics consulted Pacific Sound Control for the most appropriate product(s). They recommended a combination of the QFA-EXT-2 absorption-only blanket for locations near the engine where noise blocking in those directions is not needed but where high absorption was desired to absorb sound before it could reach the walls and roof to the sensitive direction to northeast. The QFA-EXT-2 has an absorption coefficient in the 250Hz 1/1-octave band of 0.96, or nearly 100% on average—and reducing reflections near the engine was desirable to reduce propagation of sound from the side of the pump house near the engine toward the neighbors where mitigation was desired. Then, for the critical walls and roof surfaces nearest the neighbors, the BBC-13X-2 blocking and absorption blanket was selected—a 2”-thick, outdoor rated noise blanket with both noise blocking and absorption properties to face the interior of the pump house to absorb reflections. Most importantly, this product would block transmission of noise through the pumphouse walls toward the neighbors. Although the overall or equivalent Sound Transmission Class (STC) rating of a product gives a single-number indication of its ability to block sound, an acoustic consultant will evaluate the transmission Loss (TL) for frequency band(s) of interest and attempt to select product(s) forming a solution that will block the transmission of noise through the surface or structure. In this case, the TL in the 250 Hz octave band is 20 dB. For the sake of comparison, a ½”-thick sheet of plywood has a TL of 19 dB. At this frequency band, you could argue that lining the pump house with plywood would be cheaper and nearly equivalent to using these custom-designed noise blankets. However, consider that plywood is highly reflective, i.e. does not absorb noise/sound, whereas the blankets absorb sound, particularly in the frequency band of interest here.

It is a common mistake for people to think that “acoustical panels” or “sound panels” as they are generally called on the internet will block noise—but this terminology can be misleading, because most products with that misnomer merely provide absorption of reflections, and do not block the transmission of noise through the wall/structure to rooms or locations beyond.

Pacific Sound Control supplied the materials, and they performed the installation in one day.

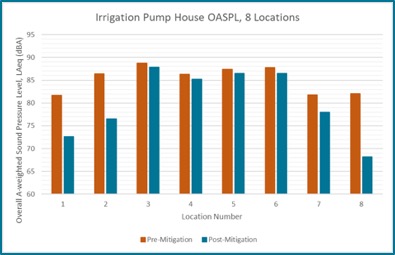

Measurements of pump house noise were performed by 45dB Acoustics personnel before and after implementing noise mitigation to the engine on site. Pre-mitigation results showed average sounds levels to range from 81 to 88 dBA; post-mitigation results indicate that a 13-dB reduction in noise levels in the direction of the neighbors was realized (positions 1, 2, and 8 in the sound level measurement chart), which is really significant! Consider that a reduction of 10dB is a 10-fold decrease in sound intensity, and is perceived as half as loud. In the other directions, noise reduction wasn’t needed, so the grey-colored panels were not installed, and so cooling for the engine was preserved.